creative engine

unites costing expertise, proficiency in methodologies and technological know‑how with people skills.

Take advantage of our expert knowledge of manufacturing techniques for electronics, semiconductor technologies and electromechanics.

Also benefit from our costing expertise in electronics materials and production as well as our ability to identify cost potential, including development of concepts to realize that potential.

Take advantage of our expert knowledge of manufacturing techniques for electronics, semiconductor technologies and electromechanics.

Also benefit from our costing expertise in electronics materials and production as well as our ability to identify cost potential, including development of concepts to realize that potential.

Leverage our many years’ experience taking a systematic, structured approach to using tried-and-tested methods and tools to achieve project goals. We apply a combination of assertiveness and adaptability that considers the people involved without losing sight of the overall goals. In addition, we apply our communication skills to find shared solutions that meet the needs of the team and the objectives of management.

Leverage our many years’ experience taking a systematic, structured approach to using tried-and-tested methods and tools to achieve project goals. We apply a combination of assertiveness and adaptability that considers the people involved without losing sight of the overall goals. In addition, we apply our communication skills to find shared solutions that meet the needs of the team and the objectives of management.

Company philosophy

Consulting focal points

Customer-oriented product optimisation

We increase your product’s value by reducing costs and/or improving performance through cost calculations, cost engineering and value engineering supplemented by TRIZ.

Methodology training

Using actual projects from your company, we introduce and train your employees in cost analysis, cost engineering, value engineering, creative methods and TRIZ.

Consulting

We support you with advice on setting up your own cost or value engineering processes and with organisational questions in value engineering. We also advise on purchasing and developing electric drives from an OEM perspective.

Market research

We clarify special questions about the market, including material data and costs, machine data and costs, supply chain analyses, component expertise and much more.

Methodology expertise

Cost calculations and cost analyses

These detailed bottom-up calculations of product costs draw on analytical principles related to materials, manufacturing processes and overhead to obtain early knowledge of product costs, evaluate bids and engage in successful price negotiations.

Cost Engineering

This methodology involves product cost optimisation in the development phase and cost reduction in series production by evaluating concepts, analysing cost drivers and potential, comparing scenarios, analysing variants and calculating the target value.

Value engineering and value analytics

This established structured method develops cost-effective, innovative and customer-oriented products through systematic, interdisciplinary collaboration, functional thinking, thorough problem analysis, advanced creative approaches to finding solutions, and the separation of solution-finding and idea evaluation.

TRIZ

Also known as the theory of inventive problem solving, this methodology develops efficient solutions to problems at a high level of inventiveness. TRIZ includes application of 76 standard solutions, 40 innovation principles and four principles of separation as well as the methods of trimming, the dwarf model and the effects database.

My profile

Education

(Dipl.-Ing.)

Graduate degree in Business Administration

(Dipl.-Wirtschafts-Ing.)

Professional experience

- Development engineer (powertrain and chassis)

- Operational cost engineer

- Head of Cost Engineering (electrical systems/electronics, software, logistics and powertrain)

- Head of Value Engineering (development of electric drive systems)

Further education

- Certified Value Engineer, VDI

- TRIZ training through level three, International TRIZ Association

- BMW management seminars

- Experienced manager program, University of Oxford

Additional expertise

- Costing in all areas of automotive electronics

- Management of a large number of value engineering projects involving development of electric drive systems; achieved cost savings of more than 20%

Projects

-

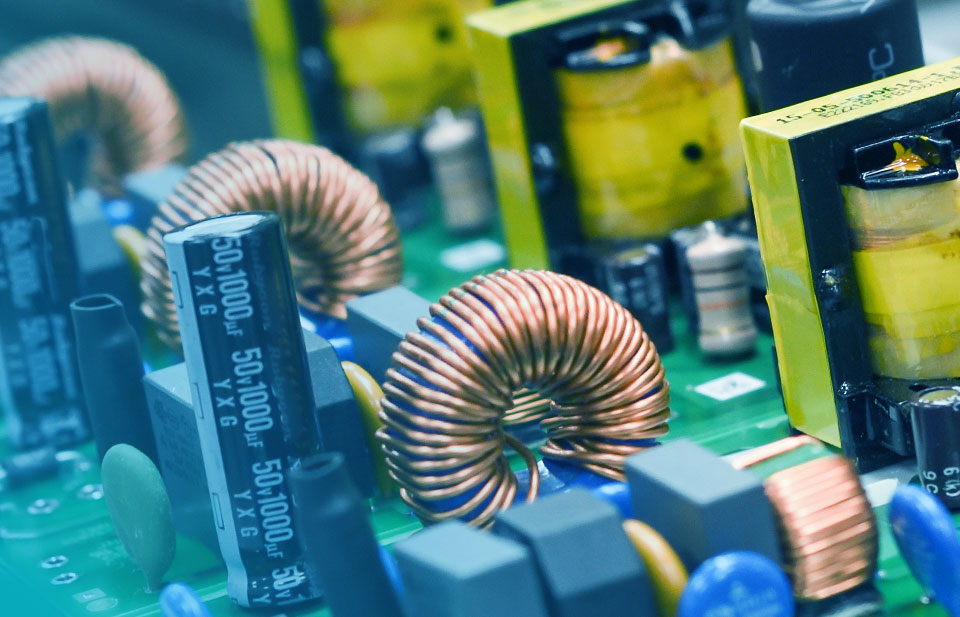

DCDC-Converter

Significantly reduced product costs for two VE projects -

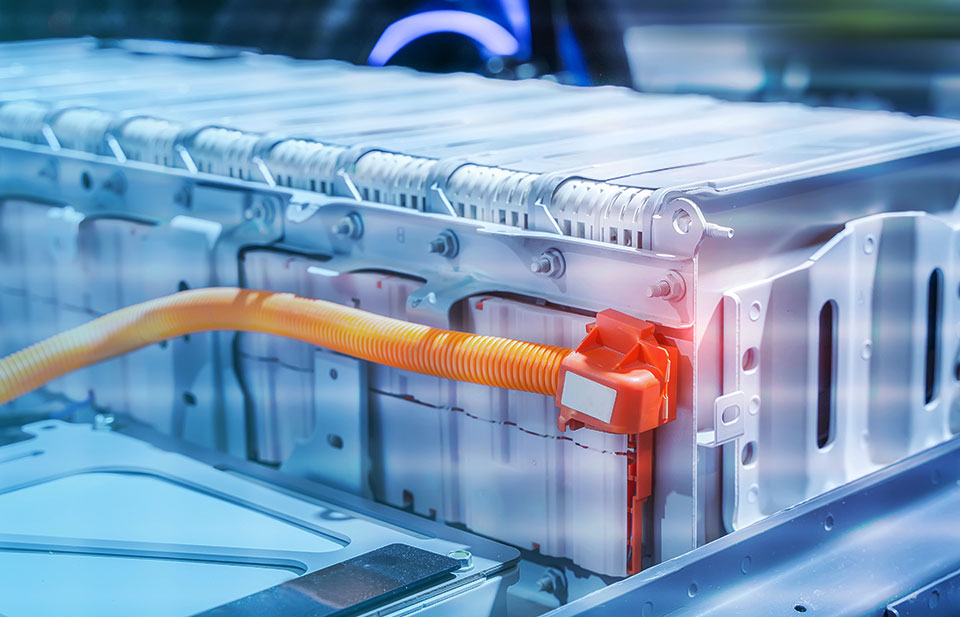

Determination of high-voltage battery temperature

Improved functioning, reduced product costs -

Inverter gate driver and gate supply

Significantly reduced product costs